HDPE PIPE MACHINE WITH HIGH output 450kg/h 50—160mm

2022-03-21

HDPE Spiral Plastic Corrugated Pipe Equipment Introduced

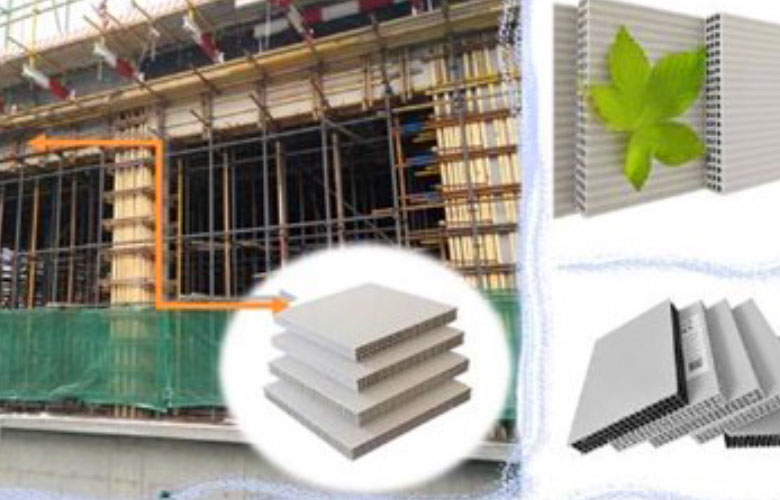

2022-04-06PP hollow building formwork is one of the new building construction materials that can replace steel formwork and bamboo glue formwork. A kind of sheet with spaces or elliptical spaces in the middle, which is formed by a single screw extruder plasticizing die setting table using polypropylene (PP) material.

Introduction of PP Hollow Building Formwork Production Equipment

The PP hollow building formwork production line manufactured by our company absorbs and digests the advanced extrusion technology at home and abroad. It is composed of automatic feeding into the single screw extruder, forming model through high-quality mold, row roller cooling device, haul off unit, Longitudinal cutter, automatic Guillotine, row roller conveyor, etc.

The unit is compact in structure and superior in performance. The screw and barrel are optimized and processed with high-performance alloy steel so that the whole machine has the advantages of uniform plasticization, stable extrusion volume, high output and long service life.

Advantages of Hollow Building Formwork

1. Short disassembly time

The hollow building formwork is connected by snaps, which is light in weight, easy to support and dismantle the formwork, simple and quick to operate, and the same building area, the hollow energy-saving building formwork saves about 40% of the time consumption compared with the traditional formwork。

And after pouring, as the temperature changes and the concrete solidifies, the formwork is automatically separated from the poured concrete and can be easily removed without beating, and the operation time will also be greatly saved. Low labor intensity and high construction efficiency.

2. Convenient and safe transportation

The density of PP hollow building formwork is only 1/21 of that of steel, and it is light in weight. A worker can easily hold a 900mm×1800mm formwork with both hands, which is convenient for handling. The formwork will not deform and absorb water during use, which can greatly improve the safety of construction, and its damage rate is less than 1‰.

3. Can be used multiple times

The PP template has the characteristics of high strength, strong toughness, impact resistance, strong elasticity, and not easy to deform. After testing, this PP template can be used more than 50 times, which can greatly reduce the construction cost.

4. Low maintenance cost

The surface of the template after use does not stick to cement, the template does not need to be cleaned, and there is no need for secondary plastering, which reduces cleaning and maintenance costs.

5. Strong machinability

PP building formwork has rigid plastic combination, high strength, lightweight, high impact strength, can be sawed, planed, nailed, cold and high temperature. It can be used with various materials such as wood (bamboo) plywood at the same time. And the use of wooden formwork is the same, and employees do not need to be retrained.

6. Environmentally friendly, pollution-free, recyclable

The waste boards and scraps of PP hollow building boards can be 100% recycled and regenerated, which saves costs and reduces pollution. The actual use cost can save more than 30% compared with traditional wood formwork.

Conclusion:

PP plastic building formwork has the commonality of conventional building formwork and more characteristics than conventional formwork. It can realize the replacement of wood with plastic, steel with plastic, and bamboo with plastic in building construction. In the near future, it will become the development of building templates. direction.