HDPE Spiral Plastic Corrugated Pipe Equipment Introduced

2022-04-06

PVC Corner Profile Production Line

2022-04-11PE Marine Pedal Market Background

China’s coastal areas have beautiful ecological environment and unique island tourism resources, especially in Qingdao, a beautiful coastal city where the company is located. With the development of marine leisure tourism and mariculture, seawater suspended cage came into being.Sea water suspended cage is a kind of suspended platform that can be placed in semi open sea areas and less affected by seasonal typhoons. According to different needs, it can be used for leisure fishing, fisherman’s Wharf, tourism, sea deep-water net cage, etc. The sea water suspended cage adopts HDPE pipe as the cage frame and provides buoyancy support. The surface is equipped with ocean pedal to form a platform structure on which people can move freely.

Ocean pedal is an important part of sea water suspended cage. With the development of industry and fishing, market demand increased, the market demand of this kind of product is also increasing. This kind of ocean pedal is not only convenient for people to walk, but also very environmentally friendly. Marine pedal production line mariculture is a production mode of raising and breeding marine economic animals and plants by using shallow waters, beaches, harbors, ponds and other sea areas. It is one of the important ways for human beings to make directional use of marine biological resources and develop marine aquaculture.

1. Introduction of PE Marine Pedal Production Equipment

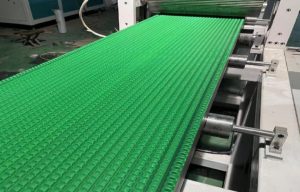

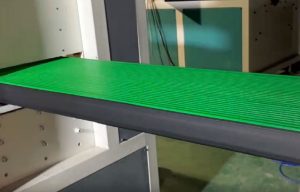

The HDPE plastic extrusion production line developed by our company takes the production of marine pedal as the standard line, uses the first and second coextrusion mode, integrates the raw materials into the coextrusion mold, extrudes the initial forming pedal through the coextrusion mold, Continuous roll molding, cools and forms the shape through the vacuum setting table of the forming pedal, finally emboss the forming pedal through the embossing machine, and is pulled to the cutting machine by the tractor to complete the ending, Our technology department has broken through its own technical difficulties and integrated advanced production technologies at home and abroad. It can well produce marine pedals with stable production process, high degree of automation, low energy consumption, high production efficiency and good quality.

2. Introduction to the Advantages of Ocean Pedal

Traditional offshore culture in net cage mainly uses wooden net cage, wooden fishing raft and plastic foam. It will cause serious pollution to the sea area before and after the production and cultivation, and it’s also weak in resisting wind waves and resisting risks.

Characteristic

The marine aquaculture pedal produced by PE marine aquaculture pedal production line takes high molecular weight high-density polyethylene (hmw hdpe) as the raw material and is extruded and formed. It is applied to various water facilities such as wharves, pontoons, platforms and so on. Its advantages are: it is a reinforced material of anti-corrosion, anti-freezing and anti purple line, and is not eroded by seawater, chemicals, chemicals, oil stains and aquatic organisms; No pollution and no damage to the environment. The marine pedal production line has the characteristics of reliable quality, preferential price, environmental protection of materials, novel design, diverse shapes and high-quality service.

Practical application of production scenario.

1: Production base of marine pedal: Suggest coastal area. Because considering the freight and the size of production, it must be as close to the sea as possible. Especially in some areas, after the completion of production, it is directly put into the seaside.

2: Application of marine pedal/fish raft: it is mainly used for deep-sea and shallow sea aquaculture, such as the aquaculture of some yellow croaker, scallop and kelp.

3: Prospect of marine pedal/fish raft: at present, due to the national planning, especially encouraging more fishermen to cultivate green fish, the state has a lot of policy subsidies in this regard, but the subsidy percentage varies according to different regions.

4: Installation and use of marine pedal/fish raft: according to different regions and applications, it is mainly composed of PE marine pedal + PE pipe + PE hollow pontoon. Then fix it with some pedal hot melt + screws. According to the requirements of fishermen, marine pedals of different sizes and specifications are produced.

Introduction to the New Technology Fish Steak

The aquaculture raft is to build an aquatic aquaculture platform in the aquaculture sea area to facilitate relevant aquatic aquaculture operations. In recent years, plastic has also been adopted as raw material, with beautiful appearance and high buoyancy

Content, construction technology and method of Plastic Fishing Raft pontoon project

1: Construction preparation: the construction personnel shall enter the construction site according to the specified time, set up material shed and living area, the price of marine pedal production equipment, purchase and transport materials into the site, connect the power supply, and contact the charterer.

2: The Plastic Fishing Raft buoy is made of plastic, with anti-corrosion, anti-ultraviolet, anti-aging, environmental protection and no pollution. The pontoon is made of polyethylene PE and HDPE, and the marine anti-skid pedal equipment is filled with polyurethane foam material.

3: During installation, the marine pedal equipment can be cultured through the hole reserved in the middle of the pontoon with stainless steel wire rope. The manufacturer of the marine pedal production line has convenient installation;

4: When the buoy is damaged after being used for many years, the damaged buoy can also be removed separately and quickly for maintenance and replacement;

5: The overall manufacturing and installation of Plastic Fishing Raft buoy shall be carried out according to the manufacturing and installation drawing of sewage intercepting buoy, and a vessel shall be rented for installation and connection during the installation period.

Conclusion:

Traditional cage culture mainly adopts wooden cages, wooden fish rows and plastic foam. Before and after production and breeding, it will cause serious pollution to the sea area, and its ability to resist wind and waves and risks is weak. At present, the project solution provided by fullwin machinery is the plastic fish raft pedal extrusion production line, which is the development trend of marine aquaculture in the future. The product has a series of advantages such as green environmental protection, recyclable, anti typhoon, anti-aging, anti-ultraviolet and so on. Ensure that the marine ecological environment is not damaged. It has been popularized abroad. Domestic coastal aquaculture areas are gradually popularized. It is mainly used in the ocean, but also in rivers, lakes, marshes, ponds, etc.