PE Marine Pedal Production Line

2022-04-08

Линия по производству защитных угловых профилей из ПВХ

2022-04-11Product Introduction:

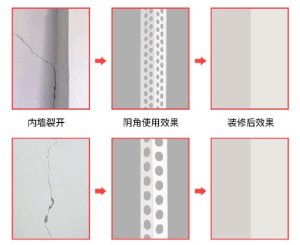

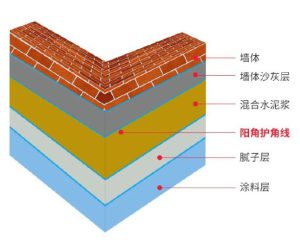

The Corner profile is a new type of building material specially designed for the difficult construction of wall corners, door corners and window corners. It is made of PVC and auxiliary agents, it is flame retardant, environmentally friendly and non-polluting. It is widely used in construction, decoration and corner enhancement and protection of old houses. It has changed the traditional method of trimming the inner and outer corners of walls by hand or borrowing simple tools and can make the corners more neat and beautiful. In addition to being beautiful, the product has the advantages of corrosion resistance, impact resistance, anti-aging, good adhesion, and full combination with putty, which greatly enhances the impact resistance of the corners and avoids dents and other damage to the corners. During use, there is no need to use the ruler plate. The operation is simple, and the construction efficiency is 2-5 times of the general one. The construction procedure is simplified and the construction speed is accelerated. Reduce engineering cost and improve engineering quality.

There are also metal corner guards on the market. The advantage of metal materials is that they are durable and have a long service life; the disadvantage is that they are easy to rust. Once the rust has passed through the surface coating, the corners can get dirty and ugly. And plastic corner beads can avoid rust, and it is more convenient to use.

PVC Corner Profile Production Line Equipment:

The production line for PVC corner profile developed by our company is mainly composed of: conical twin-screw extruder (single-screw plastic extruder), corner profile die, vacuum Calibrator machine, double-station tractor, Punching machine, Double station cutting machine, double station turning platform, punching machine, can be equipped with mixer and crusher, etc.

Equipment Advantages:

1. Extrusion by twin-screw/single-screw main machine, no need for granulation, and PVC powder is directly used for extrusion.

2. More than one mold, can extrude multiple corner guards at the same time,.3. Electromagnetic heating, power saving, energy-saving.

4. The equipment has a high degree of automation and is easy to operate.

5. Fast setting speed, energy-saving, and high output.

6. Online automatic punching, one-time completion, reducing process and labor cost.

The production line can produce various types of PVC-profiled plastic products. It has the characteristics of a high degree of automation, stable working performance, large output, high efficiency, reasonable structure and convenient use. At the same time, the unit can realize online automatic punching, which saves time and effort, and greatly increases the market competitiveness of customers’ PVC products. Our company can develop and customize various types of PVC profile production lines according to the actual needs of customers.