Fresh Air Duct Corrugated Pipe Equipment

40-110mm Double Wall Corrugated Pipe Machine

At present market, the pipe of the popular fresh air system is HDPE double wall pipe, also known as polyethylene double wall pipe. It is a new type of pipe material has the characteristics of light weight, high pressure resistance, good toughness, fast construction and long life, etc., and its excellent design of pipe wall structure make the cost of his tubes much lower than that of other tubes.

Main Features

1.Suitable to produce PE, PP pipe extrusion.The main fresh air pipe diameter is 75mm, 110mm ,Pipe diameter can be 40 to 160mm.

2.Raw Material: PP PE granule.

3.Production speed is 4-6m/min.

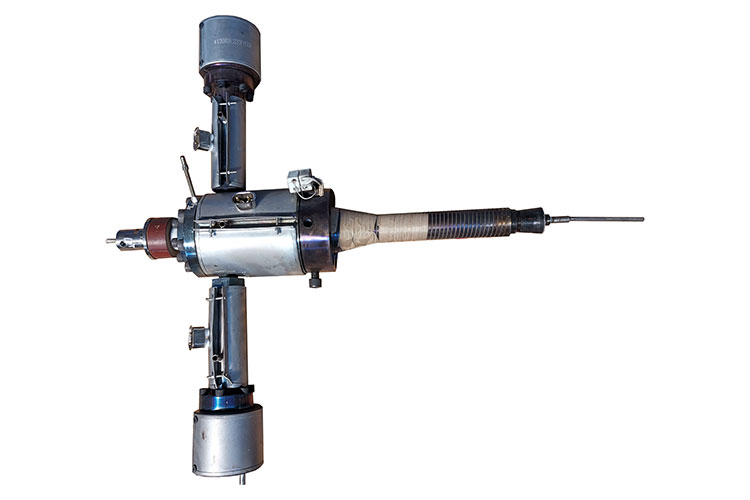

4.Mainly includes: Screw Extruder, Forming Machine, Forming Module, Cutting Machine, Stacker, Production Line Control System.

5.Supply technical service, formula guide and staple raw material purchase.

2.Raw Material: PP PE granule.

3.Production speed is 4-6m/min.

4.Mainly includes: Screw Extruder, Forming Machine, Forming Module, Cutting Machine, Stacker, Production Line Control System.

5.Supply technical service, formula guide and staple raw material purchase.

Our Advantages

1. Fullwin’s unique 6 groove double screw die head, low resistance, high pressure and stable discharge. The inner wall has a bracket, no need to adjust it.

2. The cooling water jacket is made of stainless steel, which makes it more wear-resistant and faster in thermal conductivity.

3. The new integrated mouth mould and core bar design,change the specification more easy.adjust the pipe thickness more easy,improve the customer working speed.

4. The cooling system loop on the inner side of the pipe wall at the mouth mold adopts professional heat insulation device for thermal isolation, which ensures the inner wall runner temperature is constant and even, improves the stability of inner wall molding, and makes the inner wall more beautiful.

5. Water-cooled vocuum forming machine, make the pipe corrugated more beautiful.

6. 52 pairs of molding modules, after nitriding polishing treatment, durable, 2 pairs of spare blocks for each size.

2. The cooling water jacket is made of stainless steel, which makes it more wear-resistant and faster in thermal conductivity.

3. The new integrated mouth mould and core bar design,change the specification more easy.adjust the pipe thickness more easy,improve the customer working speed.

4. The cooling system loop on the inner side of the pipe wall at the mouth mold adopts professional heat insulation device for thermal isolation, which ensures the inner wall runner temperature is constant and even, improves the stability of inner wall molding, and makes the inner wall more beautiful.

5. Water-cooled vocuum forming machine, make the pipe corrugated more beautiful.

6. 52 pairs of molding modules, after nitriding polishing treatment, durable, 2 pairs of spare blocks for each size.

Electric Parts

SIMENS Motor

ABB Frequency Converter

OMRON Temperature Control

Guomao Gear Reducer

Service

Pre-Sales Service

* online Inquiry and consulting support. 24 hours

* Sample testing support.

* View our Factory.

* whole manufacturing process traceable

* online Inquiry and consulting support. 24 hours

* Sample testing support.

* View our Factory.

* whole manufacturing process traceable

After-Sales Service

* Field installation, commissioning , operation training.

* Engineers available to service machinery overseas.

* Free spare parts.

* online service: 24 hours

* Field installation, commissioning , operation training.

* Engineers available to service machinery overseas.

* Free spare parts.

* online service: 24 hours

Packing & Deliery

Stretch Film Packaging

Wooden Box Plywood Packaging

Customized Packaging