PVC Corner Bead Profile Machine

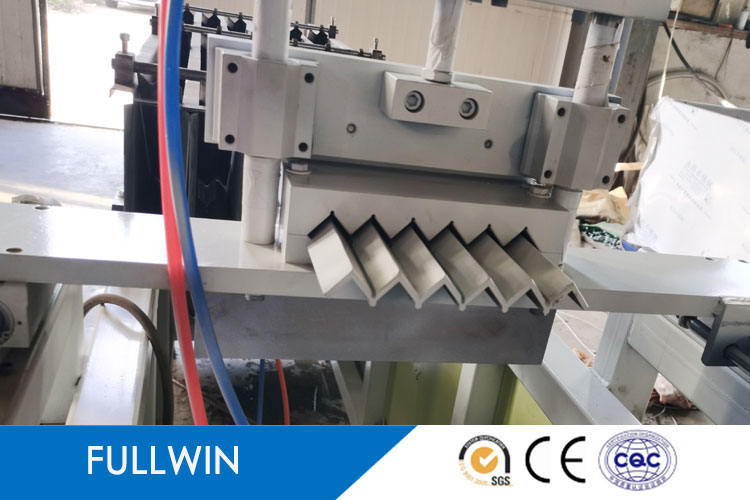

The PVC corner bead profile machine includes extruder, extrusion die, shaping die, shaping platform, tractor, cutting machine, punching machine, unloading rack, etc...

Main Features

1. Capacity: 80-150 kg/h.

2. Raw Material: PVC powder or PVC granule.

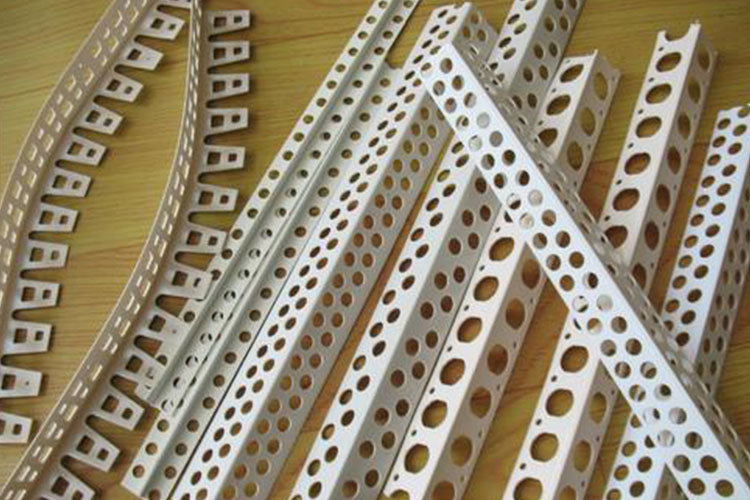

3. Classfication: metal corner protection strip, PVC plastic corner protection strip, wing corner protection strip.

4. The corner protection equipment can be extruded with a single-screw extruder or a twin-screw extruder according to customer requirements, and the mold can be customized, one for four, one for six, etc.

5. Mainly includes: extruder, extrusion die, shaping die, shaping platform, tractor, cutting machine, punching machine, unloading rack, etc.

6. Supply technical service, formula guide and staple raw material purchase.

2. Raw Material: PVC powder or PVC granule.

3. Classfication: metal corner protection strip, PVC plastic corner protection strip, wing corner protection strip.

4. The corner protection equipment can be extruded with a single-screw extruder or a twin-screw extruder according to customer requirements, and the mold can be customized, one for four, one for six, etc.

5. Mainly includes: extruder, extrusion die, shaping die, shaping platform, tractor, cutting machine, punching machine, unloading rack, etc.

6. Supply technical service, formula guide and staple raw material purchase.

Our Advantages

1. The production line is mainly composed of The production line adopts automatic control, with high degree of automation, stable equipment, simple operation and high production efficiency.

Specification

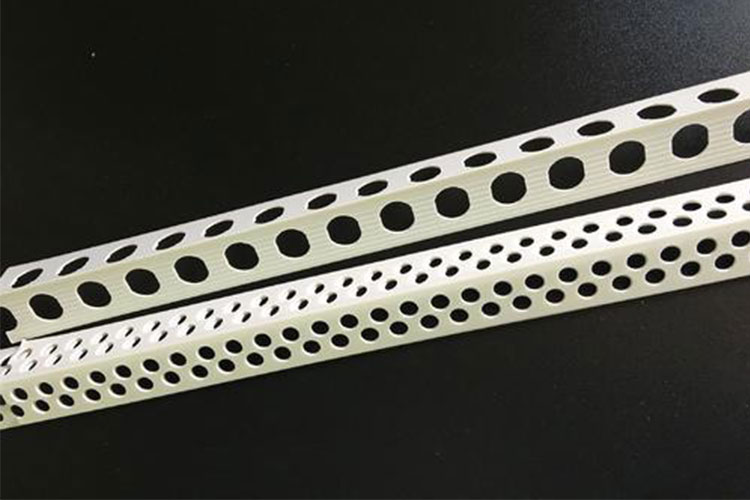

PVC corner profile production line is used to produce PVC corner. This machine Can produce ONE TO SIX corners at the same time, after extrusion the PVC corner, there is a online punching Machine, it is used to punch hole on the PVC corner.

Machine List

1.Spring feeder ZJF-300

2.Conical Double Screw Extruder (also can use single screw extruder as to customer requirement)

3. Mould

4. Vacuum calibration and cooling table

5. DoubleTractor

6. Online punching machine

7. Cutter and counting profiles

8. Crusher (used for recycling)

2.Conical Double Screw Extruder (also can use single screw extruder as to customer requirement)

3. Mould

4. Vacuum calibration and cooling table

5. DoubleTractor

6. Online punching machine

7. Cutter and counting profiles

8. Crusher (used for recycling)

Electric Parts

SIMENS Motor

ABB Frequency Converter

OMRON Temperature Control

Guomao Gear Reducer

Service

Pre-Sales Service

* online Inquiry and consulting support. 24 hours

* Sample testing support.

* View our Factory.

* whole manufacturing process traceable

* online Inquiry and consulting support. 24 hours

* Sample testing support.

* View our Factory.

* whole manufacturing process traceable

After-Sales Service

* Field installation, commissioning , operation training.

* Engineers available to service machinery overseas.

* Free spare parts.

* online service: 24 hours

* Field installation, commissioning , operation training.

* Engineers available to service machinery overseas.

* Free spare parts.

* online service: 24 hours

Packing & Deliery

Stretch Film Packaging

Wooden Box Plywood Packaging

Customized Packaging